Machine selector

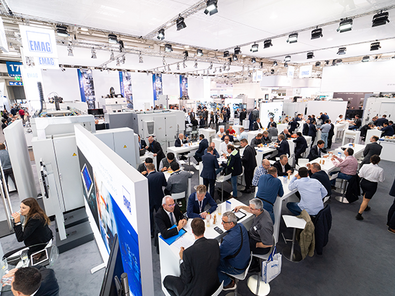

Machine Tools and Production Systems from EMAG – Our Specialty

As a manufacturer of CNC machine tools the EMAG Group masters all the processes involved in the soft and hard machining of metals. EMAG draws on an enormous range of technologies to achieve this – from turning, drilling, milling, gear cutting and grinding to laser welding and heat shrink assembly all the way to electro-chemical machining.

EMAG Webinars

Wed, 24.04.2024 10:30 - Germany Time

Webinar @ EMAG: Economical, high-precision fine machining with universal external cylindrical grinding machinesWed, 08.05.2024 10:30 - Germany Time

Webinar @ EMAG: Manufacturing high-precision piston rods - Grinding solutions from EMAG for greater efficiencyCurrent events

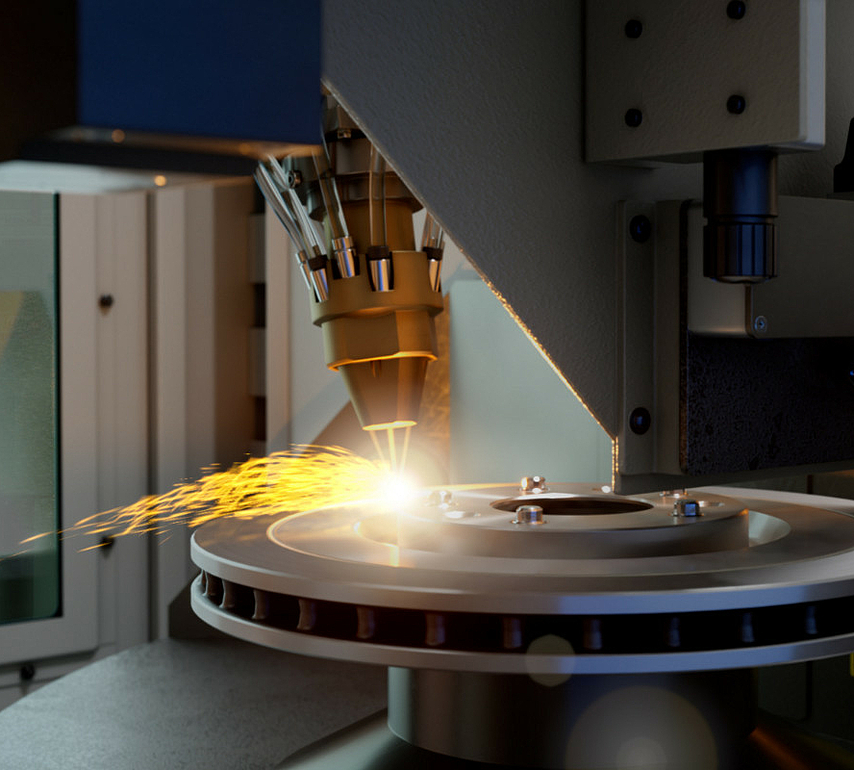

Laser Metal Deposition

High Volume Brake Disc Production: Laser Metal Deposition for Efficient Processing

Euro 7 standard mandates lower non-emmisions particulate matter - the previous passenger car brake disc is to become obsolete and discontinued model. For the new generation of brake discs, EMAG, along with its technology partner HPL Technologies offer a complete solution for the hard coating of brake discs by laser metal deposition – the process-is safe, efficient and fast.

More Information Laser Metal DepositionRotor Shafts

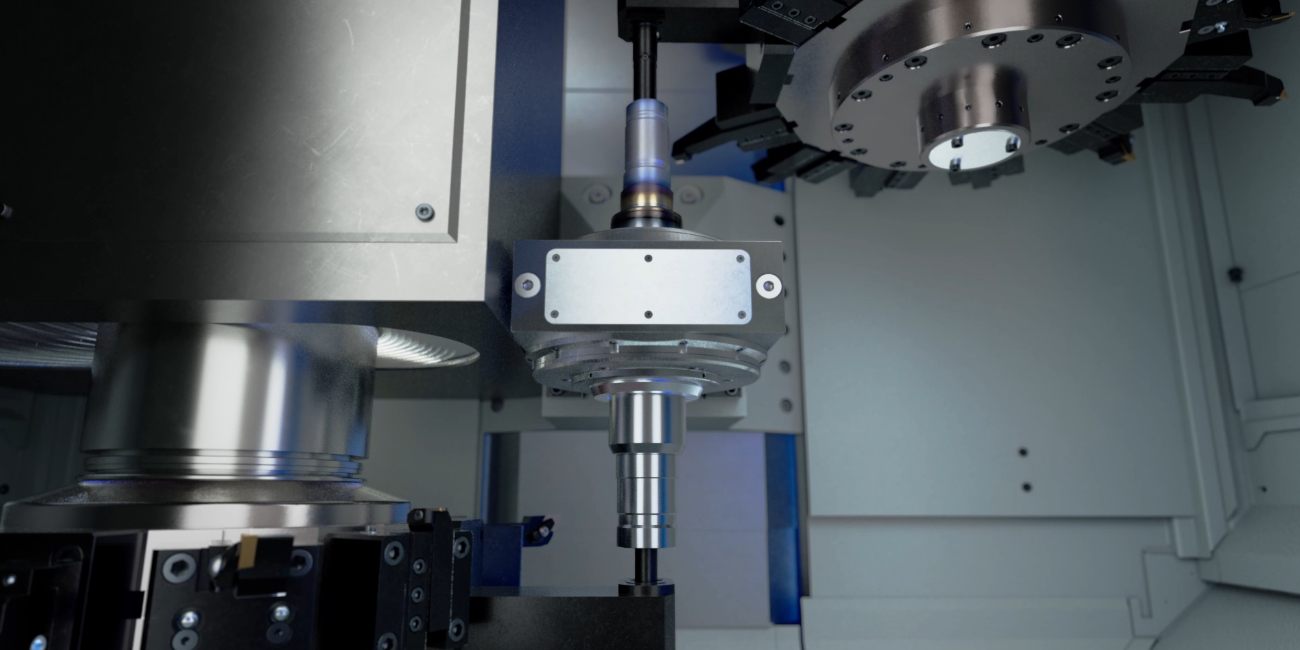

Producing Rotor Shafts on a Fully Automated Line

EMAG designs and constructs complete production lines for one-piece or two-piece rotor shafts.

More informationEMAG News

Latest Posts

04/19/2024 - Blog

WPG 7 from EMAG: Perfect cylindrical grinding on the smallest footprint