Grinding has been employed in manufacturing for more than 100 years although the earliest grinding practice goes back to neolithic times thanks to the Homo Sapiens activities. Size reduction is infact the oldest engineering process started right in prehistoric times.

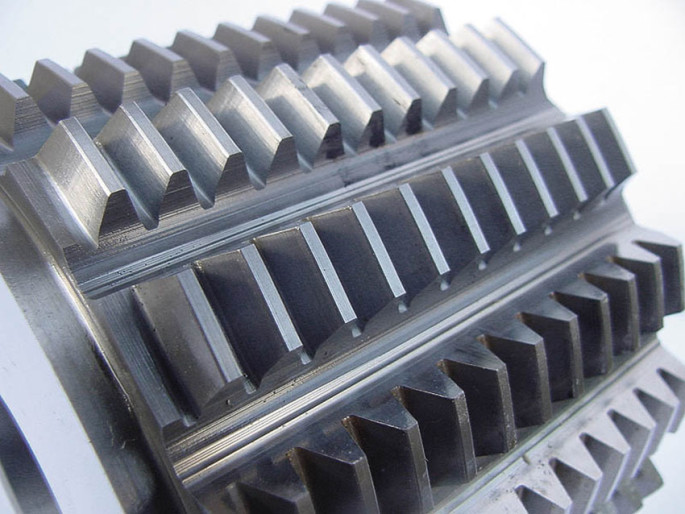

As the years go by there is an evolution from stones, mortal and pestle, saddlestone mill, larger querns driven by animals, water wheels until the 20th century that is defined as the modern grinding process birth. Indeed, the grinding process achieves his scientific basic from 1914 thanks to the seminal publications by Alden and Guest. Since then grinding is defined as a machining process thant employs an abrasive grinding wheel rotating at high speed to remove material from a softer material.

Nowadays in modern industry the grinding process is carried out thanks to machine tools which combine computer-controlled feed-drives and slide-way motions, allowing complex shapes to be manufactured free from manual intervention.

Grinding evolution has also increased grinding wheel speed and removal rates: they boosted by two to ten times over the last century.

Also the abrasive types have evolved by ensuring advances in productivity. As a matter of fact, new ceramic abrasives based on sol gel technology have been introduced together with the development of superabrasive cubic boron nitride (CBN) and diamond abrasive based on natural and synthetic diamond.

Productivity has also been increased thanks to the insertion of new grinding fluids and methods of delivering grinding fluid. These fluids have also been an essential part in achieving higher removal rates and maintaining quality.

In recent years, grinding evolution has passed through the inclusion of high-velocity jets, shoe nozzles, factory-centralized delivery systems, neat mineral oils, synthetic oils, vegetable ester oils and new additives. Minimum quantity lubrication provides an alternative to flood and jet delivery aimed at environment-friendly manufacturing.

Thanks to all of this innovation, today grinding is a key technology for production of advanced products and surfaces in a wide range of industries.