- All

- Know-how

Grinding has been employed in manufaturing for more than 100 years although the earliest grinding practice goes back to neolithic times thanks to the Homo Sapiens activities. Size reduction is infact the oldest engineering process started right in prehistoric...

An important element of the gear hob design is the tip relief which represents a relief of the tooth profile and a part of the Archimedean spiral. The Archimedean spiral is a curve traced out by a point moving...

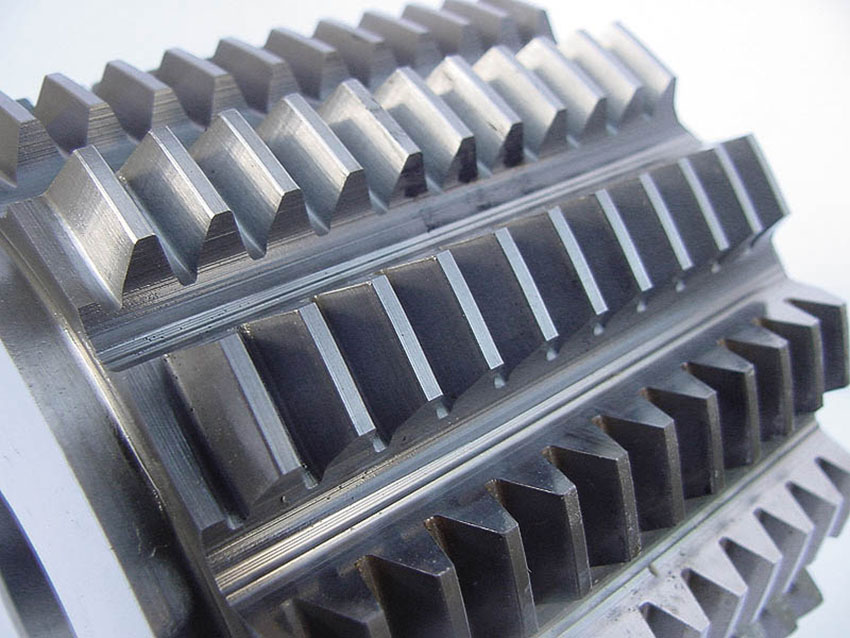

A gear hob is a gear cutting tool composed of different parts. The main parameter characterizing a gear hob is the module, which is the result of the division between the pitch gear diameter and the number of the...