Since many years, shaving is known as a big batch production gear finishing process in the automotive and truck industry.

Samputensili has several decades of experience in the design and manufacture of shaving cutters. Here also, the rising demands in precision and high tool life have led to continuous improvements of the existing technology.

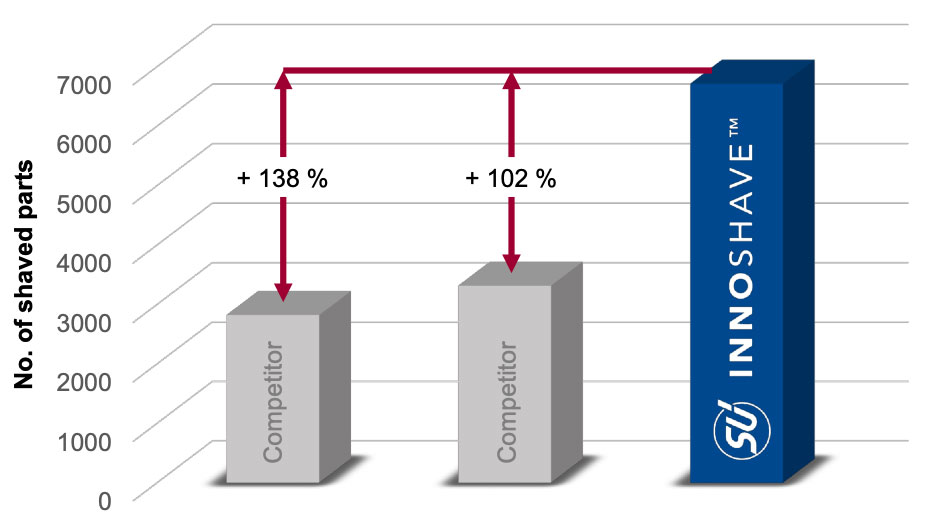

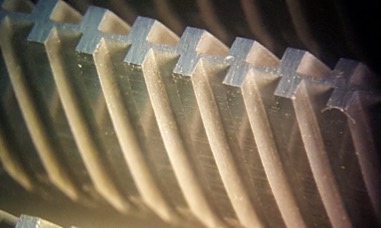

The introduction of the latest shaving cutter generation, the INNOshave™, offers our customers a new level of highly productive shaving cutters. At Samputensili, experts are using the newest technologies available to generate the new INNOshave™ tools, which ensure superior performances compared to standard shaving cutters. The INNOshave™ features a very sharp and precise cutting edge along the serrations, thanks to which the tool cuts the workpiece much more easily. Furthermore, the chip evacuation is improved and the load on the tool decreases. If, after a standard sharpening process, the shaving cutter wears out, the INNOshave™ presents a new precise cutting edge with the same high quality. The recent improvements were shown in the reported test results. The graphic shows the result of a shaving application on a module mn = 2 mm automotive gear. During the tests, the Samputensili INNOshave™ has shown its superiority against state-of-the-art shaving cutters of our main competitors.

The standard shaving cutters of both of our competitors had to be changed after 2800 – 3300 shaved parts. The INNOshave™ ran much longer and reached 6700 shaved parts. This translates into a tool life improvement by up to 138% thanks to the INNOshave™, which brings down customer´s tool cost per piece. Also after resharpening the same high level of tool life was achieved.

Catalogue Downloads